Hydrogen & Fuel cell engineering

The prominence of global warming has resulted in urgent demand for sustainable/clean energy sources, releasing minimal pollutants and leaving a small carbon footprint, such as hydrogen energy. Due to such a trend, electrolytic cell(EC) and fuel cell(FC) gain a lot of attention for its application in hydrogen and energy production. Among various types of EC/FC, solid oxide electrolytic cell(SOEC) and solid oxide fuel cell (SOFC) show great promise thanks to its high operating temperature resulting in enhanced efficiency, easy heat recovery, and not requiring precious metal catalysts. However, high temperature is also the cause of various problems which degrade stack performance and durability consequently hindering its longevity. Our objective is to enhance the robustness of solid oxide cell(SOC) stack and hot box using the following approaches:

- Analyzing thermal/electrochemical phenomena within a SOC stack and hotbox

- Suggesting a novel SOC design for enhanced thermal management

- Optimizing the operation protocol of a SOC stack and hotbox

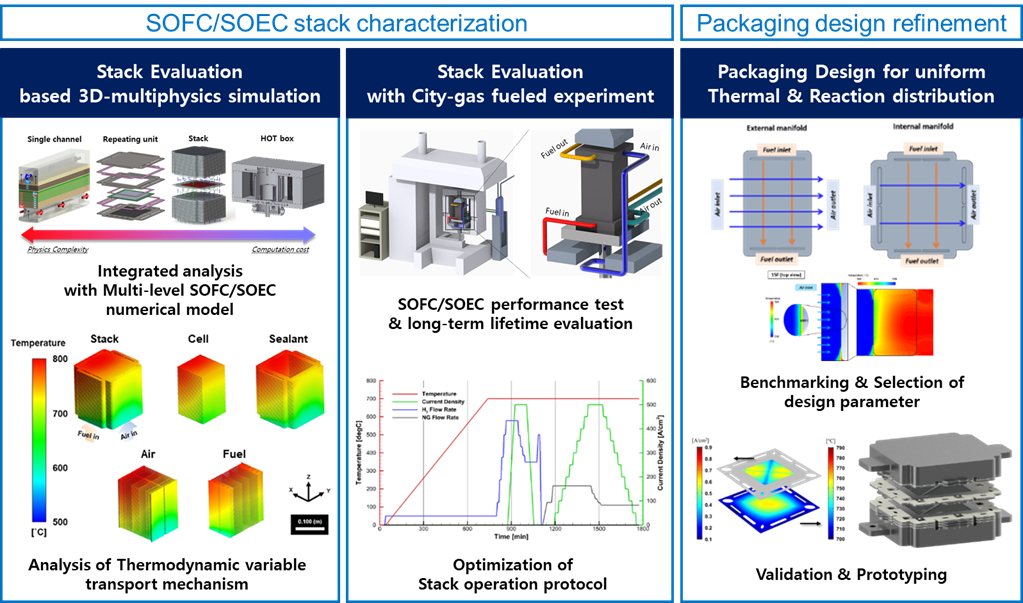

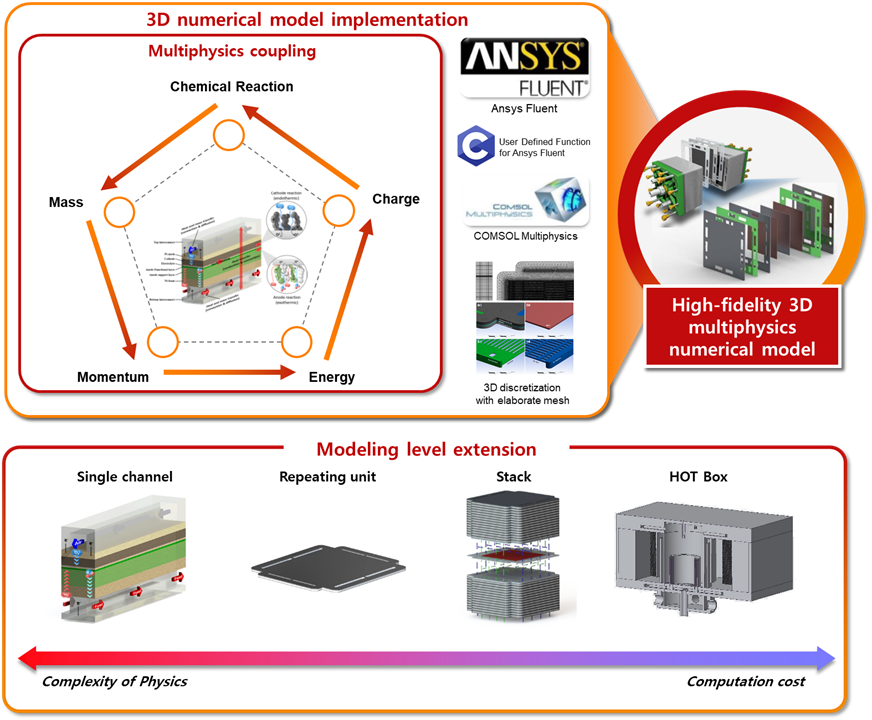

1. Development of a high reliability numerical model for SOFC/SOEC

A complete SOFC/SOEC system includes a variety of components and entails thermal/electrochemical complexities that tend to vary with scale, which must be elucidated by numerical simulations. As a numerical model becomes more sophisticated, computational costs will inevitably increase. Therefore, a compromise has to be made between accuracy and computational cost. In order to guarantee high reliability within all ranges, stepwise comparisons between models with different scales are performed from narrow to wide scales to prevent any derailment upon compromising certain features. In addition, the models used are calibrated using data from in-house experiments to further increase the accuracy.

Main topic

: High-fidelity 3D computational model development

References

[1] Lee et al. International Journal of Heat and Mass Transfer, 9 (2016) 77-93.

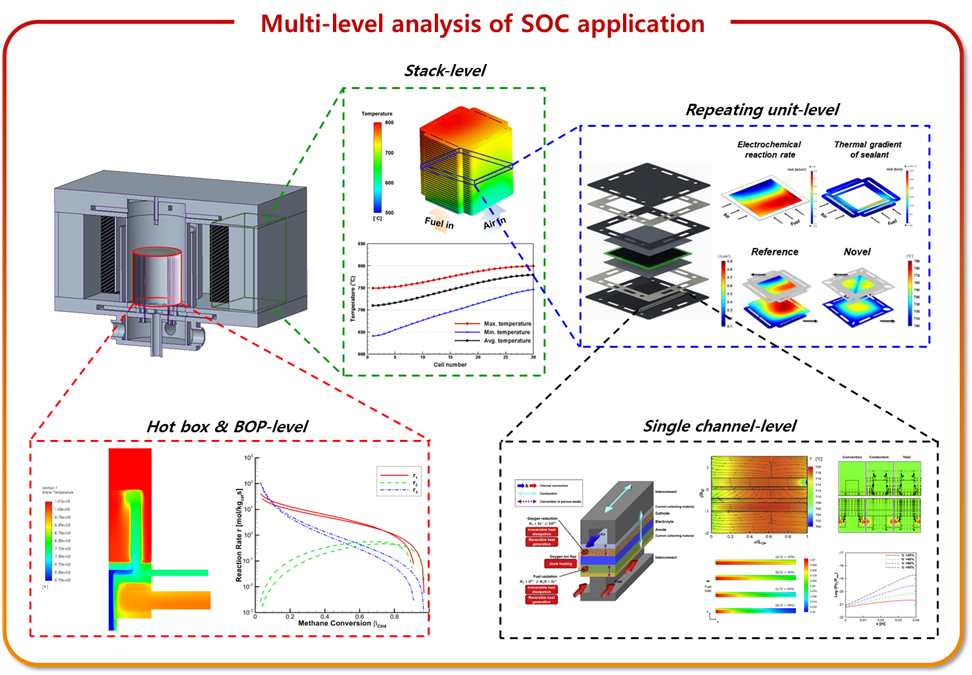

2. Elucidating local states and internal transport mechanism of SOFC/SOEC

To improve the performance and lifespan of a SOC stack, it is necessary to have detailed insights into its internal physics. Using MES laboratory’s 3D numerical SOC model, detailed physical/electrochemical mechanisms can be clarified. To satisfy the purpose, the MES laboratory resolves numerically a SOC single channel with highly detailed electrochemical and thermodynamic variables, a repeating unit with flow/current collecting structure, a stack with detailed thermal analysis, and a hot box & balance of plant with a rather simplified stack and fuel reformer model. Based on such models, local thermodynamic states within a SOC stack are examined, and heat and mass transport mechanism is elucidated, which provides insights into the roadmap for an efficient and reliable stack design.

Main topic

: Thermodynamic(energy, mass, momentum) transport mechanism analysis

References

[1] Lee et al. International Journal of Heat and Mass Transfer, 97 (2016) 77.

[2] Lee et al. Energy, 120 (2017) 293.

[3] Lee at al. Energy Conversion and Management, 174 (2018) 565.

[4] Kim at al. Energy Conversion and Management, 222 (2020) 113213.

[5] Bae at al. Energy Conversion and Management, 165 (2018) 405.

[6] Bae at al. Energy Conversion and Management, 201 (2019) 112152.

3. Novel design of a SOFC/SOEC stack for thermal management

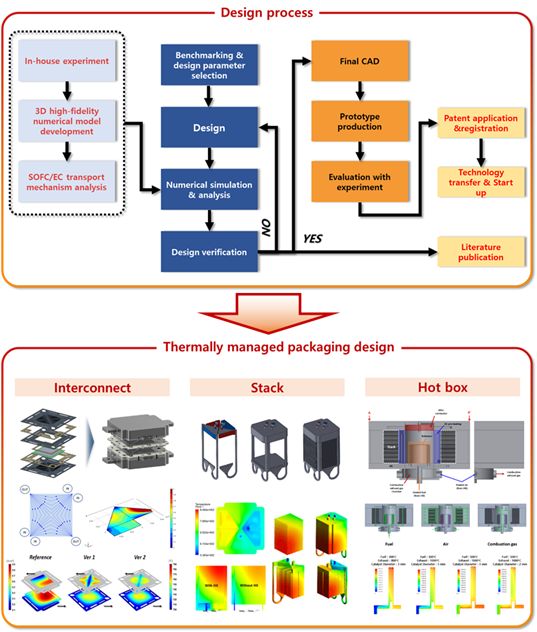

Based on the multiphysics simulation results, the MES laboratory proposes a thermally and electrically improved packaging design. The design process begins with selecting design parameters through patent and paper benchmarking. The optimal design derived through the process of analysis and brainstorming is verified by numerical analysis and then linked with patent application and technology transfer. Breakthrough designs with enhanced thermal management of an interconnect, stack, and hot box are developed, which leads to a number of patent application/registration and technology transfer.

Main topic

: Thermally-managed SOFC/SOEC package design

: Numerical & Experimental validation

References

[1] KR Patent 10-2018-0169046 (2018), U.S. Patent 16/556,007 (2019), JP Patent 2019-157908 (2019)

[2] KR Patent 10-2018-0106095 (2018), U.S. Patent 16/287,296 (2019), JP Patent 2019-041280 (2019)

[3] KR Patent 10-2018-0036939 (2018), U.S. Patent 16/170649 (2018)

[4] KR Patent 10-2020-0081197 (2020)

[5] KR Patent 10-2020-0116163 (2020)

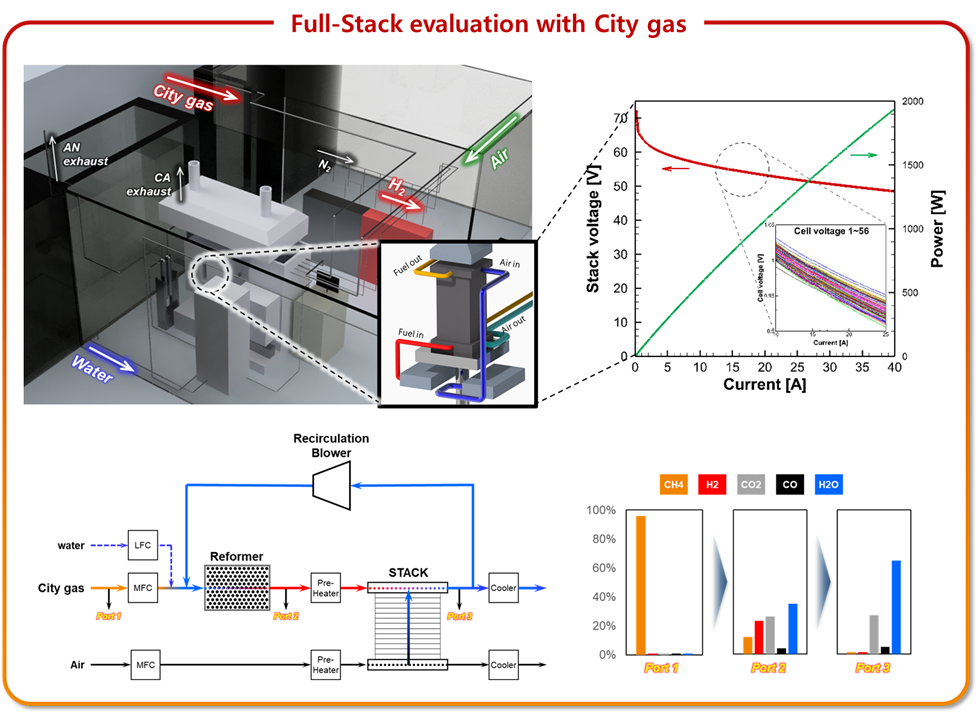

4. Experimental SOFC/SOEC stack evaluation and operation protocol refining

One of the most important issues in recent SOFC/SOEC stack development is to extend the life of the stack to ensure the economics of the fuel cell system. Hence, it is crucial not only to improve the packaging design and materials used, but also to understand the conditions under which the stack will not deteriorate and operate the system within those conditions. The MES laboratory has set up an experimental device to perform commercial-level (>1kW) SOFC/SOEC stack evaluation. This device can be used to assess the life of an actual stack and derive improved operating protocols. This SOFC/SOEC stack evaluation device has stable anodic and cathodic gas supply lines for long-term experiments. Especially, it can utilize not only hydrogen but also city gas, that is actually used inside a building, as a fuel. In order to utilize city gas as a fuel, a separate reformer, desulfurizer, water purifier, and heat exchanger are installed in this device.

Main topic

: Commercial level (> 1 kW) SOFC/SOEC stack evaluation (IVP, lifetime, cycling)

: City-gas fueled and Optional fuel recirculated SOFC evaluation

: Operation protocol optimization